News

UPCYCLING MINERAL BY-PRODUCTS & WASTES THROUGH INNOVATION

WE HAVE ‘REACHED THE LIMITS’ OF THE PLANET’S NATURAL RESOURCES

Unsustainable use of natural resources is having a severe impact on our environment. With the megatrend of urbanization and the increasing number of people living in cities, it is expected that natural resources such as sand and aggregates will continue to be depleted without replenishment.

ZaaK has been researching and developing innovative technologies to upcycle mineral wastes and by-products into value-added products for sustainable management of our natural resources. Our commitment is to give new life to these unused by-products or waste materials.

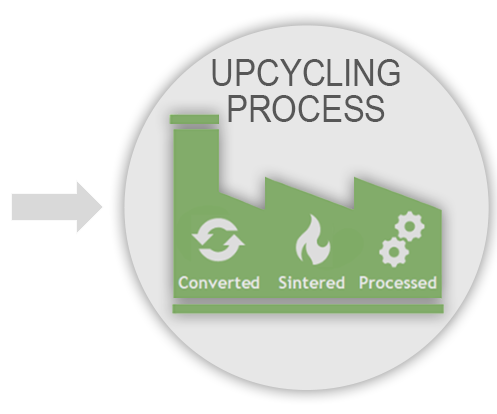

With its proprietary technologies, ZaaK offers a single-step solution to the environmental impacts of mineral wastes and by-products. ZaaK’s upcycling technologies transform unused wastes and by-products into sustainable lightweight sand, called Lypors®. This is an ideal secondary raw material that acts as a substitute for natural sand and can be used in the construction sector and other industries.

Lypors® Technology

Upcycling instead of only recycling or disposal.

A progressive solution to the age-old problem of wastes and by-products.

The challenges faced by producers of mineral wastes and by-products require viable and forward-looking solutions. To safeguard our socio-economic future, technologies that promote the achievement of sustainable development goals and veer towards circular economy are greatly needed.

By upcycling these wastes and by-products into high performance building materials ZaaK is providing a progressive solution to drastically reduce disposal problems, and pushing the waste-producing industries like thermal power, alumina and waste-to-energy plants towards a zero-waste scenario and greener cities.

ZaaK’s processes ensure these wastes and by-products can be effectively utilized instead of being disposed or deposited. At the same time, it offers an ecological secondary raw material to the construction industry.

LYPORS®

What is Lypors®:

Lypors® is a well size-graded lightweight sand manufactured from mineral wastes and by-products. It is a premium quality and a cost-effective construction sand material with diverse applications.

Where Lypors® can be used:

Lypors® can be used in different applications such as:

- Lightweight concrete

- Lightweight masonry mortar

- Thermal insulating plaster

- Lightweight roof tiles

- Lightweight façade

- Tile adhesive

- Screeds and others

Benefits of using Lypors® :

- Ready to use

- Superior and consistent quality

- Well-balanced between lightweight and good strength

- Thermal and sound insulation

- Longer service life of buildings/infrastructures

Contact Us to learn more about Lypors®

LYPLAST®

What is Lyplast®?

Where Lyplast® can be used:

Benefits of using Lyplast®:

- Lightweight – easy to lift, transport and plaster

- Thermal insulating

- Excellent workability

- Less rebound

- Excellent surface finishing

- Good adhesion on various substrate

- Improves labor productivity

Contact Us to learn more about Lyplast®

LYTAR®

What is Lytar®?

Where Lytar® can be used:

Benefits of using Lytar®:

- Lightweight – easy to lift, transport and plaster

- Excellent strength

- Good workability

- Good adhesion

- Improves labor productivity

Contact Us to learn more about Lytar®

LYCRETE®

What is Lycrete®?

Lycrete® is a lightweight dry ready-mix concrete in accordance with DIN EN 206-1:2000

Where Lycrete® can be used:

It is suitable for various concrete work such as the production of screed constructions, foundations, door, and window lintels

Benefits of using Lycrete®:

- Excellent strength-to-weight ratio

- Thermal insulating

- Good workability

- Fire resistance

- Energy savings from heating/cooling buildings

Contact Us to learn more about Lycrete®

Input Streams

Solutions for a wide range of mineral streams.

Irrespective of the input streams, the final Lypors® material conforms to…

Coal combustion ash

Lypors® technology is extremely versatile and can handle any types of coal combustion products whether they are freshly produced or deposited, hard coal ash, brown coal ash or a mixture of both ashes.

Biomass-coal co-combustion ashes

Lypors® technology is versatile and handles biomass-coal co- combustion products whether they are freshly produced or deposited.

Waste-to-energy ash

ZaaK is one of the first companies which started to develop a solution for incineration ashes, also known as waste-to-energy ash, which to a large part until now have been deposited underground.

Bauxite residue

Lypors® technology is extremely flexible and can handle different types of bauxite residue streams whether they are freshly produced or deposited.

Sustainability

Lypors® is a prime example of sustainability.

…whether it is production, transportation, construction, building, living or reuse.

Lypors® is a prime example of sustainability demonstrated throughout its entire life cycle from its production, transportation, use in construction, service life or reuse.

Production

Up to 95%

of the raw material constituents are mineral by-products or wastes

Construction

Up to 32%

Concrete and reinforcement savings

Transportation

Up to 25%

fuel savings in transporting Lypors

Living

> 350%

better thermal insulation factor

Re-use

100%

Recyclable

Lypors® technology offers a very meaningful step to achieve twin objectives:

- – Upcycling mineral wastes and by-products into a value-added construction sand and

- – Minimizing consumption of sand, a finite natural resource

Lypors® is addressing the Sustainable Development Goals defined by the United nations regarding sustainable cities and communities as well as responsible consumption and production.

Services

One stop solution.

Together with leading industry players in the design and engineering fields, ZaaK offers tailored solution to thermal power stations, alumina refineries and waste-to-energy incineration plants.

Turnkey Solution

Our turnkey solution involves:

- Feasibility study

- Concept development

- Detailed engineering

- Fabrication

- Installation & commissioning

- Training & handover

End-to-End Solution

In this model we accompany our clients from the start to finish to achieve zero waste. Our end-to-end solution involves:

- Lab & pilot testing's

- Customize Lypors® process

- Turnkey solution

- O&M service

- Buy-back of Lypors® product

Waste off-take

We present our clients with the opportunity to upcycle their mineral wastes and by-products into eco-friendly Lypors® material. We offer them sustainable and economical solutions to dispose off their mineral wastes and by-products.

About Us

Shaping the Future of Construction.

ZaaK Technologies is an innovative company with expertise in transforming mineral wastes and by-products into sustainable construction materials.

ZaaK Technologies is an innovative company with expertise in transforming mineral wastes and by-products into sustainable construction materials. Using awards-winning and proprietary clean technologies, ZaaK intends to shape the future of the building and construction industry using its flagship product, Lypors®. This is made possible through the upcycling of wastes and by-products into high-end products that are safe and sustainable for construction.

We task ourselves with the handling, treatment and utilization of wastes in an environmentally friendly manner, resulting in economic and sustainable solutions. Lypors® has positive effects on energy efficiency of buildings and smart cities while, raw material efficiency reduces other environmental impacts and increases national resource security. Our products have a favorable impact on the product value chain in terms of socioeconomics and the environment.

OUR MISSION

Our goal is to help expedite the transition to a sustainable future by facilitating investment in eco-friendly resources that help save and rebuild our immediate environment.

OUR CORE VALUES

The Planet

We make an effort to consider the environmental impact of every decision we make. Reducing the carbon footprint and the by-products of our clients‘ activities and our own will contribute to our planet’s long-term viability.

This is, indeed, a collaborative effort. We invest in ourselves and the people in the places where we work in order to clean up the earth. We can’t achieve anything on our own.

We Are Purpose Driven

A shared purpose is created when we are all on the same page about our mission. We work relentlessly to come up with the best ideas, get outcomes, and open doors that would otherwise be closed. We will not stop till the job is completed.

We Are Authentic

We set an example by doing our best to help save the planet, and preserve our environment.

Partners

ZaaK Technologies GmbH

Am Wall 8a

14979 Großbeeren

Germany